Offshore resonant test system for 66 kV inter-array cables

As the scale and quantity of offshore wind farms increase the requirements for robust commissioning methods is also increasing. This is especially true for wind farms that have adopted 66 kV inter-array cables (IAC) to accommodate increasing power generation.

Traditionally VLF has been used offshore due to its relative portability. However, since this test runs at 0.1 Hz or lower to negate the large capacitive load that a long length of cable provides, this technology is not really a pertinent test for AC power systems. Due to the higher voltages and thus electric field stresses in 66 kV systems it is critical that a 'proper' AC test voltage is used to stress the system to identify any points of weakness that could lead to a costly failure further down the line. IEC 63026 was published in January 2020 and for cables greater than 36 kV stipulates that a test frequency of 10-500 Hz must be used for commissioning. This rules out the use of VLF completely.

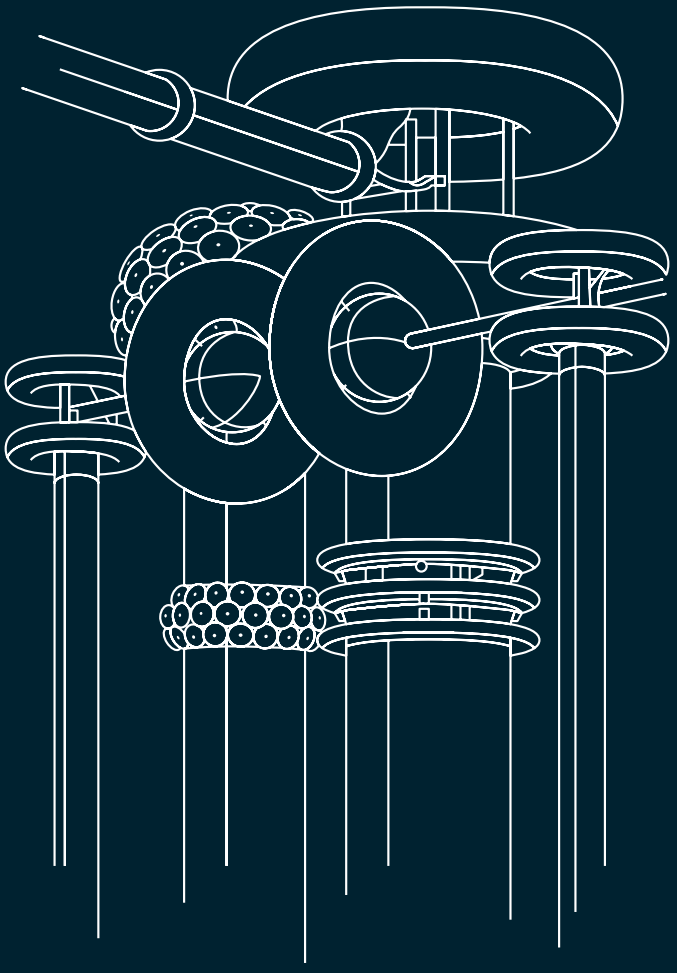

In partnership with a large offshore wind stakeholder, HIGHVOLT have developed a mobile, lightweight and modular resonant test system (RTS) targeted specifically at offshore commissioning of IACs operating up to 66 kV. This system is composed of a variable frequency feeder unit, a number of modular reactors (the number required is dependent upon the type and length of cable to be tested), a collection point, and a connection point including a coupling capacitor and blocking impedance for partial discharge tests.

Each component is designed to be lifted by crane or forklift and the heaviest component (the reactors) are either 3.7 tonnes or 5 tonnes depending on the model. This limit was imposed in the design process to ensure each component could be craned from a supply vessel onto the switching platform. The supply container and resonant reactors are also CSC certified and compliant with IEC 60721 ) Once assembled and the cable to be tested is connected the system will automatically find resonance and so minimise the power required to perform a full voltage test.

The benefits of using RTS over other test technologies include:

- Test voltage and frequency as per IEC 63026

- Continuous voltage applied (rated for 60 minutes) - ideal for partial discharge testing where defects may not present themselves immediately

- By using resonance the power required to test is limited

- Modular nature of the system means a large range of loads and voltages are possible (additional reactors may be required, but equally for some projects a small number of reactors may be required)

See below for further specification of the system. For more information please contact me.